Your First Tractor

This is our tractor. It is a Kubota L3901. 36HP (32@PTO), L525 loader, backhoe, hydrostatic transmission. When we bought it, we didn't know very much

about tractors, so we've made a few mistakes. Hopefully this write-up will allow you to learn on ours.

A tractor is an incredibly versatile machine. It can do a lot of things - plow a field, dig a trench, level an area, clear away brush, lift heavy things.

After first few months on the farm I started seriously asking myself this question - exactly how did I manage to live most of my life without one?

For example, getting something heavy into a house or a garage in Seattle is an ordeal. With a tractor, you just attach forks to the loader

and go to town. I can load anything into a truck and unload anything from the truck.

It turns out, life on a farm involves a lot of loading and unloading. And snow removal. And hole digging.

So let's talk about tractors.

Do I have to have a tractor?

Yes. If you plan to do anything with the land, or access it in winter, it is a requirement.

Tractor basics

This is a tractor in its minimal configuration.

The black metal structure above the tractor is called "Roll-Over Protection System", or ROPS. Tractors often go on

uneven terrain, and tractor roll-overs is one of the top causes of death among farmers. All modern tractors have ROPS,

(some are built into the cabin) but many older ones don't. I recommend against buying tractors without this system.

You will thank me for this recommendation when you have to load your tractor on a trailer for service.

In its most basic form a tractor can pull behind agricultural machinery. Like this:

At the rear end of the tractor there is a shaft called "PTO" - power take-off - that can supply power to mechanisms attached

behind the tractor. For example, the baler above does not run itself - it uses the tractor for its power. The power is transferred

using PTO shaft - a telescoping system that connects to the tractor's PTO on one end and extends to the implement's mechanism

on the other end.

It looks like this.

Right by the PTO shaft at the rear end of the tractor is a system that's called "3-point hitch".

It consists of two lower arms that tractor can lift up and down, and a passive upper arm (top link) that is not powered

but helps hold whatever is mounted on the hitch in the air.

Here is a post hole differ - a mechanism that can bore 2-4' holes in the earth - mounted on a three point hitch.

A super useful attachment for a tractor is a front-end loader. You should not buy a tractor without it.

A tractor's loader is often shown with a bucket attached to it, but you can also mount loader forks, a snow blade, or even, my favorite,

a grapple. This thing lets you rip roots and brush out of the ground. It also costs considerable extra, and requires an extra

set of hydraulics and controls.

Loaders have different coupling standards for attachments, if you are buying an older tractor, it helps to understand

what coupler style its loader supports, because you can be limited by availability of implements that

fit it. Also, some older copuler styles can be a pain to operate. More information is available

here. Avoid pin-on models

if at all possible. You are welcome!

Another cool attachment is a backhoe. A tractor mounted backhoe is nowhere near as powerful or fast as an excavator, but it

is a tiny fraction of the price and it sure beats a shovel. You can dig a hole with a backhoe in half an hour that would

take you a day or even more with a shovel.

When you buy a tractor, the cost of even the basic implements can easily double the price of tractor. And after that the haying

or planting equipment can double the price again. If the budget is constrained, I would recommend prioritizing as follows:

- Tractor power. This will not be correctable in the future - once you bought it, you are stuck with it.

- Loader. This is the most useful implement. Loaders come with a bucket.

- Loader forks. They are the least expensive and the most useful of loader attachments.

- Snowblower. This will stay on your tractor all winter.

- Backhoe.

- Everything else.

Sizes

When we bought our LA3901 we've made a mistake. It was just too small. When we bought it, our farm was only 20 acres and the planned use was mostly

moving things around, clearing land, and snow removal. But since then our land grew considerably, we now have fields to till and crops to plant -

and most agricultural devices - they are called "implements" - require far more powerful tractors.

Tractors come in several categories, roughly matched to power of the engine.

First, there are lawn tractors. Those are basically just lawnmovers in a tractor shape. They can mow the lawn and with a snow thrower

attachment they can help moving snow. They cannot do much else.

They can be useful on a large property, and in fact I own one just like this, but they are not really tractors and they are

not essential to rural life, so I am not going to discuss them.

Next come subcompact tractors. These are the ones with the engines up to about 25HP. They are just like real

tractors, only small, and they can be immensely useful on the property. If this is all you can afford, buy this.

A sub-compact tractor has a few advantages.

First, they are extremely maneuverable. They can fit in places where a bigger tractor won't and so with the loader

forks attachment, they can deliver payload everywhere.

Second, these tractors often have a mid PTO which allows mounting a snowblower at the front. Like so:

On larger tractors snowblowers are mounted to the rear three point hitch, and the tractor has to be driven

backwards to clean the snow. On a large property backing up with your neck turned can become old quickly.

This is what I do for a couple hours almost every weekend in winter:

Alternatively a snowblower must come with its own motor. Which means that there is an extra engine to pay for,

fuel, maintain, and repair.

Tractors are not cheap, but sub-compact tractors are the least expensive. You can typically buy them with

just the loader for $15-20k, and more powerful models with a backhoe go for $20-25k.

The main disadvantage of a sub-compact tractor is lack of power. It cannot move most of agricultural machinery used in haying,

seeding, or plowing. Special small implements made in Italy are available for these super small tractors, but good luck finding

anyone who services them locally, and because the swath they cut through the field is much smaller than normal, it would

take a very long time to hay anything but a very small field with them. I don't think seeding equipment is even available.

On a loader, the lift capacity is around 500lb. Your typical pallet forks would take 200lb right off the bat for themselves, leaving

you only 300lb of payload weight. 300lb is just five 60lb concrete bags. Or not quite four 80lb bags. Or just 3 100lb hay bales.

That's really not a lot. There is not much you can do with this loader.

One level up from here is compact tractor class.

These machines is where the designation "tractor" should start. Before that, they are just multifunctional lawn mowers.

Kubota L3901 is a typical representative of this class.

The loader here is not ridiculously underpowered - it cal lift 1200lb off the ground and to 5 feet high. 3 point hitch can

lift 1600lb, which is sufficient for vast majority of 3pt mountable equipment. The hitch itself is category I, which,

again, is the majority of 3pt mountable equipment.

You can use the tractor to unload most things from a truck - a standby generator, or a snowmobile, or a pellet stove.

You can have it carry 12 80lb bags of concrete, or a budle of wooden fence posts - though not effortlessly. It can clean

a large swath of your driveway from snow - with a snowblower or a plow. With a backhoe, it can dig a 6' trench.

What it cannot do is agricultural work. Most seeders, hay equipment, and large disks require a 50hp plus tractors.

Like with subcompact tractors, compact haying equipment from Italy is available for this power range.

As above, finding a dealer who can fix these machines or has parts may be a challenge, and many more trips

through the field result in more time spent and more trampled crops.

Here is an example of low-power haying machines:

https://tractortoolsdirect.com/showroom/tm-pro-hay-package/.

We bought our L3901 with a few implements (including a grapple) for $40k with tax. Basic model with just a loader

should cost under $30k.

So now we get to the tractor class that you need to have if you want to do agricultural work - the utility tractor.

Utility tractors are available starting from about 50HP to about 140HP. The prices go from

approximately $50k on a 50HP machine with a cab and a loader to about $70-80k for a 100HP machine

with a cab and a loader. Adding backhoe and extra valves can send the 100HP machine into

almost $90k range.

Because PTO power is 10-15% below the engine speed, and most of the ag implements require at least 50HP at PTO,

the lowest practical engine power for haying is at least 60HP. At this power level you will still be limited

to the least powerful "standard" implements with the narrowest processing path, so I think the sweet

spot is actually somewhere close to 100HP.

Tractors around 100HP have PTO at around 90HP, close to 2 tons of lift capacity at the loader pin (it can lift

your Prius), and it will operate more or less anything in terms of ag equipment.

This is for haying. If you are on a small farm in Eastern WA, haying is what you will most likely be doing -

the predominant crops here are hay, wheat, apples, grapes, and hops, but everything else requires either

very expensive equipment or major commitment of money and effort, and usually both - so really only hay

is within the means of a weekend farmer.

You can check out the full range of ag products that are grown in WA

here.

The big problem with utility tractors is transmission. All models but the lowest powered

ones come with manual transmission (see below).

Beyond utility tractors there is an "agriculture" tractor segment. These are really large, really powerful (around 200HP)

machines that can operate all kinds of harvester equipment. They are too big for a small farm, and I don't have any experience

with them.

Transmission and drive

Tractors have two types of transmission - hydrostatic (HST) transmission, which is automatic, and manual. HST transmission is

the simplest to operate. There is a range selector - low, medium, high that sets the gear range. And then there are two pedals - forward

and reverse. The farther you press on the pedal, the faster the tractor goes. If you just touch it a little bit, the tractor crawls

forward or back. If you don't press any pedal, the tractor does not move (unless it is on a steep slope).

For a beginner, the HST transmission is the most forgiving. The tractor often needs to be navigated through VERY tight spots (tractors

are exceptionally maneuverable!) and automatic transmission makes it very, very easy.

Unfortunately, past 60HP they simply don't make tractors with HST, so you are probably stuck with the manual transmission.

60HP is what you will have to have if you want both haying and automatic transmission, and it may be OK, but you will

be VERY limited on the implements.

Manual transmission on a tractor is easier to deal with than that on a car - there is no gas pedal,

the throttle is controlled by hand, so the two legs that a normal human has are sufficient for

operating the brake and the clutch.

Still, creeping forward or backwards very slowly is what tractors do when mounting implements -

you need to drive the machine exactly into the right place to hook stuff up. This is especially

true with things like backhoe or the loader. And this is much much much harder to do with the

manual transmission. Gods help you if you will ever have to mount a backhoe on a slope (or any

type of uneven surface where a tractor with the clutch pedal pushed in just rolls).

Also, some implements - trencher attachments, for example - require a super low speed that cannot

be achieved even at the lowest standard manual transmission gear.

To that end, tractors can have so called "creeper" kits installed as an option, which add another

"super low" gear range. I strongly recommend getting this option. Again, you are welcome!

Most modern tractors are 4WD. Most older tractors are 2WD. The terrain and conditions that a typical tractor has to navigate - muddy,

fluffy land, snow - make 4WD very, very handy. 4WD tractors can be operated in 4WD or 2WD mode - and are usually run in 2WD mode when

4WD is not necessary.

Most tractors have a differential lock - an option that makes all powered wheels rotate synchronously, even if some wheels slip.

This allows a tractor to get out of a tough spot - but it should never be used continuously, as it destroys the tires.

You can learn more about how this works here.

Hydraulics and remotes

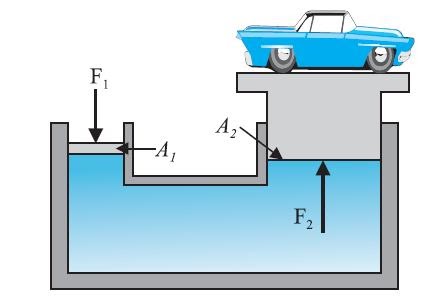

Most tractor functions - the loader, the 3 point hitch, the backhoe - are powered by hydraulics. These systems consist of hydraulic

lines, cylinders, valves, and a pump. The pump produces pressure in the hydraulic fluid, which, when the valve opens, flows into

cylinders. The force is pressure multiplied by the area, so even a very small pressure produced by a pump can create a great force

if the area of the piston in the cylinder is very large.

The controls that open and close valves are called "remotes" - because they are accessible from the tractor seat and actuate the

valves that are elsewhere on the tractor.

A lot of hydraulics are options that are installed by a dealer, so you need to make sure they put them on your tractor before you

take delivery. For example, there should be a hydraulic line and a remote that operates it on the loader in addition to normal

loader controls - without it you will not be able to mount a root grapple. This remote opens and closes the jaws of the

grapple (or changes the angle of the front-mounted snow plow, or...).

There should also be a hydraulic circuit for the backhoe, without a remote, and at least one other circuit (two are better), with

the remote, to operate some agricultural implements that require hydraulic controls.

The dealer

When you are buying a piece of equipment, you are really buying a dealer. The dealer will perform the warranty repairs, install

options, and maintain your tractor if you don't do it yourself. (There is A LOT of work on a farm, chances are, you will simply

not have time to maintain your tractor yourself even if you would want to do it). Unlike car dealerships in urban areas, the

dealerships for tractors and other specialized equipment such as ATVs, UTVs, snowmobiles, and the like are few and far between,

especially in rural areas.

If you buy a piece of equipment from a dealer you end up not liking, another option may be four hours away. By the way, this would be

four hours of towing your tractor on a trailer, and you will probably not have space to store that trailer near the dealership.

After a disaster with an Intimidator UTV which made me really live this problem (Intimidator is a particularly crappy company which

will absolutely not cooperate with anyone who tries to repair their products - and the closest dealership is in Montana), I ended

up buying all the agricultural machinery from one Kubota dealership near Wenatchee. This works great - once a year they come to my

farm, pick up all the stuff that needs to be maintained, take it to Wenatchee and bring it back the next week, for a tidy sum of $225

(plus the cost of maintenance, obviously).

I strongly recommend getting the feedback from the neighbors and perusing Yelp to learn about the quality of dealers in the area

before settling on the brand. Dealer network is really more important than the factory. One good thing is, poor dealers don't

usually survive in rural areas where word travels fast and community is too small to live off one-time customers. So my experience

with most of the dealers around my farm was actually pretty good.

The brand

Like I wrote above, the brand is less important than the dealer - go with the best dealer in the area. But if you do have a few

options, here are a few notes that may be helpful.

John Deere is obviously the most respected tractor brand in the US, and in theory should be the no-brainer choice. Unfortunately,

it isn't. Apparently, they DRM major parts of their tractors, and a dealer "activation" is required when these parts are replaced.

I find this ridiculous - the lifetime of a tractor is many decades, and I don't want to make a $100k investment in a thing

that is so tied to the manufacturer that it cannot be repaired without their participation.

You can find more about this controversy here:

Unfortunately, even low horsepower (50-60HP) tractors have this problem.

Other popular tractors are Kubota, Mahindra, Massey Ferguson, and New Holland. I am not qualified to compare them on the merits - you

would have to research that on your own if there are multiple good dealers in your area. I went with Kubota because of the dealer.

I am not unhappy with this choice.

A word of advice - do not let the small difference in price guide your decision. These machines will last for 50 years, a $5000 difference

in price over this period of time is really nothing. Also, beware of super cheap chinese models without the dealer infrastructure to

service them - such as these NorTrack machines.

They do break often, and there is no one to service them when they do.

The implements

Haying equipment deserves its own post, so I will not cover it here. For now, this is a good overview of different options:

https://www.extension.iastate.edu/smallfarms/buyers-guide-hay-equipment.

So here I will focus on a few "non-agricultural" attachments that I have found useful.

Front of the tractor

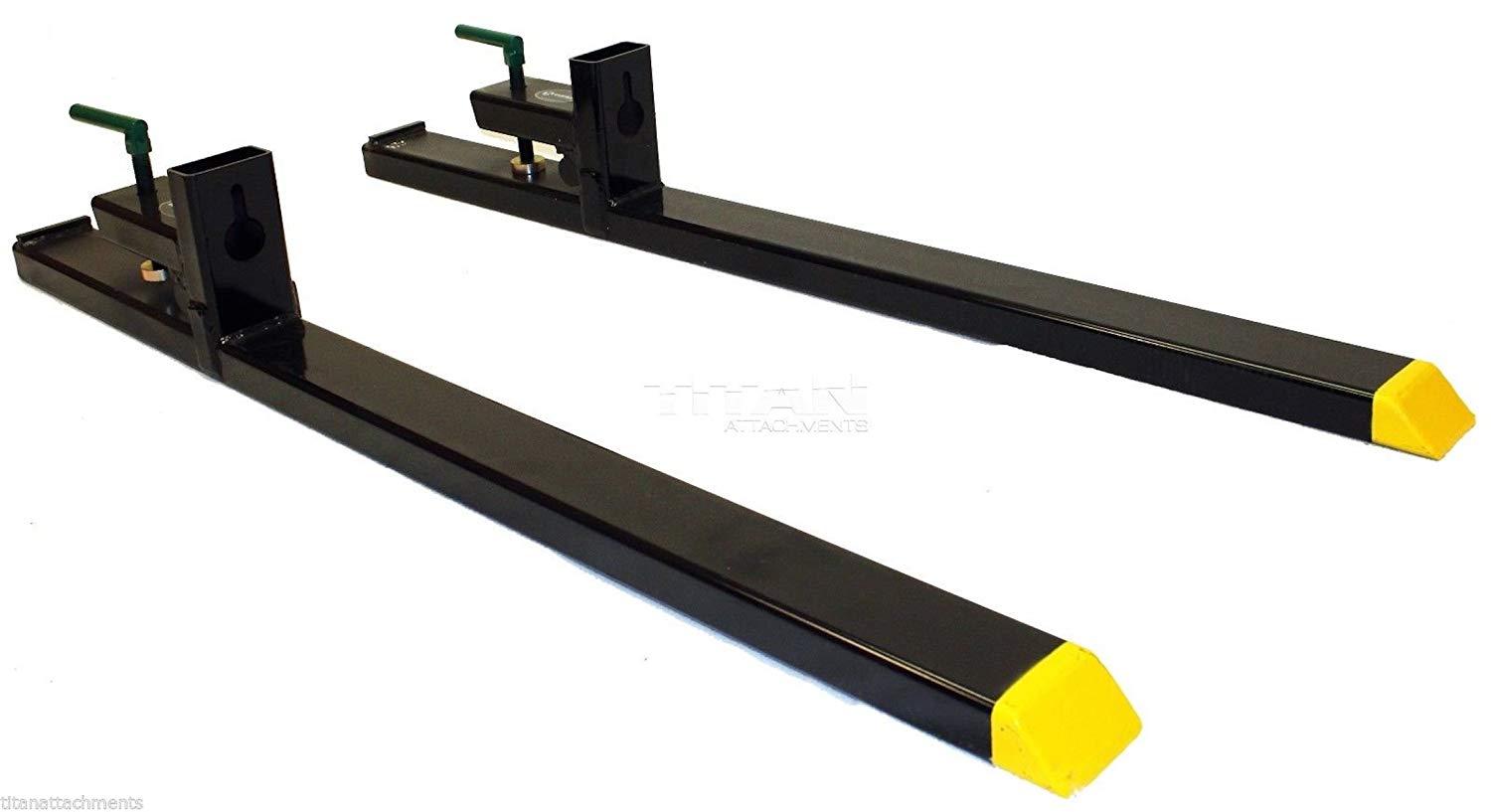

First, the loader. As I pointed out, in a non-agricultural context this is the single most useful part of the tractor. In my opinion

buying a tractor without the loader is just insane. The loader will typically come with a bucket, but most of the time I have pallet

forks mounted on it. Though you can use the bucket to carry things around, using pallets is much more conveniet.

Proper forks are surprisingly expensive - as of this writing they go for about $600 on Amazon. A hefty part of it is doubtless shipping,

because they weigh around 200lb. Nevertheless, you want forks that REPLACE the bucket, not mount on the bucket. For example, these are no-no:

Yes, they are cheap, but they are nowhere near strong enough.

A less used, but expensive front-loader attachment is root grapple.

Whenever I need to clean a patch of land, this is the number one implement.

They also make a loader-mounted plow. In the beginning I thought that the bucket would be enough for pushing snow. It turned out

not to be the case - the bucket is hard-mounted on the loader, so it either bites into the road or passes way above it to be useful.

A front-mounted plow is hung on a flexible coupler and skids - so it hugs the road when it is plowed. I bought it, used it once, and decided

that the snow blower is far, far more convenient. In Eastern WA you either have to have a snowblower or a plow, there is no other way though.

They cost about the same - around $2k.

The Land Pride snowplow (STB15) seems to be pretty well made compared to the plows I saw on the Internet when researching this article.

Rear of the tractor

The most important 3 point implement you can have in Eastern WA is a snow blower. Tons of companies make them, they all seem to be just above

$2k, and I am sure they all work well. There are different models for different tractor horsepowers, so pick the one that matches your tractor.

The only alternative to a snowblower is a plow. You have to have one or the other, otherwise you are not making up the driveway half the time in winter. The price

is approximately the same, but a snowblower is much easier to use - the plow pushes the snow so you still have to have a place for it somewhere, whereas

snowblower throws it far, far out of the way.

They do, by the way, make rear mounted snow plows. These are cheap alternatives to either a snow plow or a snow blower, because they are usually in

$400-500 range.

The principal problem here is that you have to get the tractor go on the snowfield and only after that it will be clearing the path behind it.

And that snow field may have 4 feet of snow in it (say you are using the tractor to pull out a stuck snowmobile). This mean less traction for

the tractor, but I did see these plows used successfully. I have never used one myself.

The second most useful (and the most expensive) rear-mounted machine is a backhoe. Depending on the tractor size, they go from six to twelve thousand dollars.

Obviously, backhoe is not necessary if you have an excavator. Unlike an excavator, backhoe must be stationary during the digging process, and cannot

drive away with a bucketfull of stuff and return once the bucket is dumped. It cannot dig as deep or as fast as an excavator. It cannot be used for

grading. But a new small excavator is $50k, so usually a backhoe has to do.

Backhoe makes a lot of digging jobs a breeze. There is a surprisingly large number of digging jobs at a farm.

Backhoes are available for most tractors, both from the tractor manufacturer as well as third party, and even used. I would recommend getting one

with the tractor, or at least made for this specific tractor, if at all possible. If cash is a problem, it can always be bought later.

Backhoes have differently sized buckets for different tasks. Narrower (12" and below) buckets are for diffing trenches, a 16" bucket is considered a good

all-purpose bucket. They often has an accessory called "thumb" that is useful when a stone or a log has to be picked up. Sometimes the thumb has its own

hydraulic circuit allowing it to move, but most often it is fixed in position.

The third most useful implement that I have is a post hole digger. It allows digging 2-3' holes in the ground.

They are invaluable when building fences, sheds, or anything else that requires putting wooden posts in the ground. At $400-$600 they are not

very expensive.

Another cheap and very useful attachment is a receiver adapter to 3 point hitch. This allows hitching a trailer to the tractor.

I use it when I need to back up a trailer into a tight parking position. It is 100 times easier with the tractor than with a car.

These things usually cost around $100. Price/performance - one of the best investments in my life.

These I use a lot every year. There are a few implements that I own that are useful in principle, but I don't use them much.

The most important is box scraper. This is used for road grading and ground leveling. It is in theory an extremely useful implement - but using

it requires quite a bit of skill, which I currently do not possess.

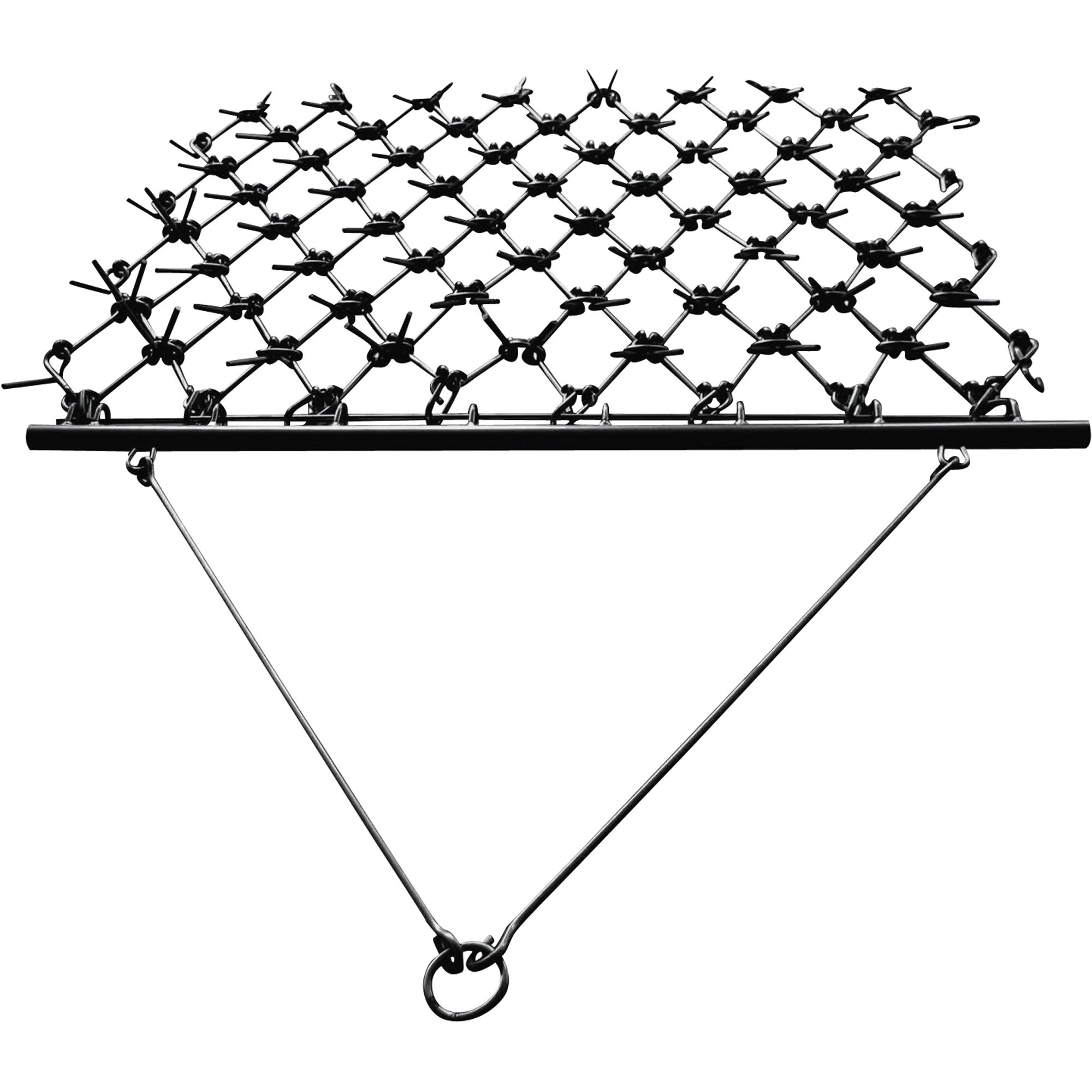

A drag harrow attaches to the draw bar behind the tractor and can do a little bit of earth conditioning. It is inexpensive ($200) and easy to use

- as long as you only move forward.

I also own a few implements that are tractor mounted versions of machines that are more commonly powered by dedicated motors - a log splitter

and a chipper. The motivation here was that with a tractor I don't have to maintain a whole separate engine that I would use only once or

twice a year and then have to change oil, drain the gas, and otherwise prep it for a long term storage.

But the downside of it is - the tractor versions of this machinery are more expensive, and of course running a tractor is far more expensive

than running a small, cheap motor - just in tractor engine maintenance costs per hour.

Brush hog - the tractor version of the lawnmover - takes the cake as the least useful tractor implement I have. I used it once. I doubt I will

ever use it again. I just don't have a big enough lawn. The least useful $1200 I have ever spent.

By the way, speaking of useless, while browsing around, I noticed that they sell a device that is designed to adapt 3 point hitch to a car or a SUV.

Don't!

This does not work. This cannot work. Most 3 point implements are very heavy. Even the smallest tractors are capable of lifting at least 1000lb.

Your typical car? Not so much. Tongue weight - how much you can hang on the receiver hitch - is roughly 10% of towing capacity. A typical

passenger car towing capacity is only 1500lb - so the tongue weight is 150lb. It's even less for UTVs. The hitch adapter itself is 80lb,

so you may be able to hook a large suitcase with the remaining capacity, no more.

A typical large SUV can tow 4500lb - so the maximum tongue weight is 450lb. My Jeep with a towing package can do 7200lb - this is where you can maybe

start hooking anything interesting to that three point hitch adapter. But even then a hitch never fits into the car receiver snugly, so the

stability of this thing is super questionable.

Yes, you really do have to have a tractor.

Used or new?

As I wrote before, tractors last a VERY long time - generations. For this reason, the prices don't drop that much over time.

Because of that, in my opinion, a new machine is preferred over a used one - $10k difference on something that costs $50k amortized

over 20-30 years is only a few hundred dollars a year, but it buys you a peace of mind and a warranty.

Dealer demo models - which are sold as new with a new warranty, but often at quite a discount - are the sweet spot, however, if you can

find one.